Last Saturday, I attended Jiro-sensei’s bamboo accessory workshop. It was a special treat to see the beautiful Japanese basketry exhibits and observe a master artisan at work, explaining how bamboo is processed and the higo or bamboo strips are made.

The higo needs to be soaked in water to make it malleable enough to twist and bend. Depending on the thickness on the strips, the pre-soak is anywhere between 7-30 minutes. When I received my hand-out it seemed simple enough with clear instructions on interlocking of the higo.

The higo needs to be soaked in water to make it malleable enough to twist and bend. Depending on the thickness on the strips, the pre-soak is anywhere between 7-30 minutes. When I received my hand-out it seemed simple enough with clear instructions on interlocking of the higo.

The first step is to form the bottom grid panel. Somehow, I wasn’t able to get the final step right which involves locking the panel in place. When I would lift the panel, all the sticks would simply fall apart! Finally, after about ten attempts, I managed to crack it.

The first step is to form the bottom grid panel. Somehow, I wasn’t able to get the final step right which involves locking the panel in place. When I would lift the panel, all the sticks would simply fall apart! Finally, after about ten attempts, I managed to crack it.

It is important to keep the higo hydrated as you work. Occasional quick dips in the water are a must; otherwise the higo will break when you’re trying to bend it.

When making smaller objects ( I was making pendants ), the criss-crossing in the bottom grid needs to be as close as possible. So one needs to carefully keep moving and aligning the sticks closer and closer to each other. Once this base is ready, the higo can be twisted and bent to start forming the shapes.

When making smaller objects ( I was making pendants ), the criss-crossing in the bottom grid needs to be as close as possible. So one needs to carefully keep moving and aligning the sticks closer and closer to each other. Once this base is ready, the higo can be twisted and bent to start forming the shapes.

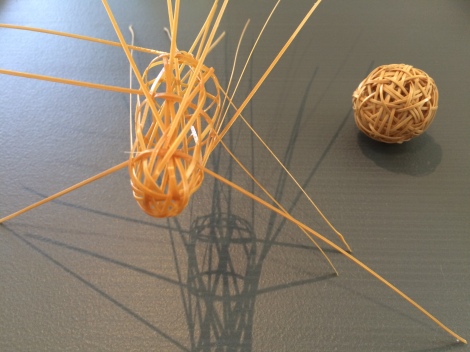

My work in progress below.

I chose the easy organic route to interlocking, so there isn’t a discernible specific pattern/weave. I think it turned out pretty neat nevertheless.

I chose the easy organic route to interlocking, so there isn’t a discernible specific pattern/weave. I think it turned out pretty neat nevertheless.

Now, I need to decide whether to dye them in kaki-shibu, indigo or leave them as is! Suggestions?

Now, I need to decide whether to dye them in kaki-shibu, indigo or leave them as is! Suggestions?

xoa

PS >> Special thanks to my gracious employer + mentor Yoshiko, who sponsored this workshop for me!

Beautiful!

LikeLike

Thanks Kim! It was great experience meeting Jiro-san and learning something new.

LikeLike